Tubes as an Ideal Packaging Solution

We impress you with the benefits of the laminated tube

Laminated tubes are used worldwide for packaging in the cosmetic, oral care, food, and pharmaceutical industries, and for tubes from industrial areas.

A benefit of these tubes is that they demonstrate excellent barrier properties, which increases in particular the durability of the products. The smooth, flexible, and soft outer surface enables excellent sealing of the tube material (e.g. on the side seams).

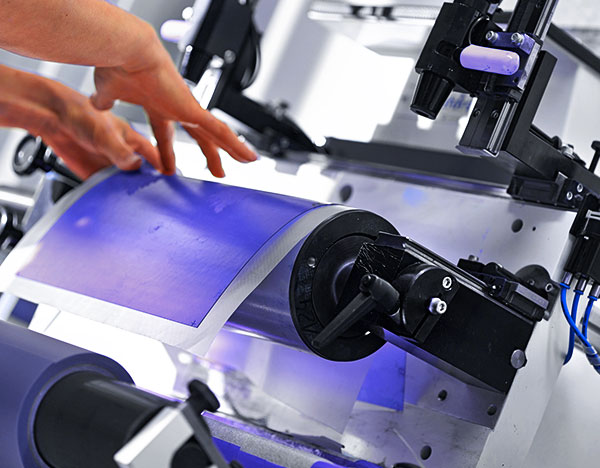

The printing process precedes tube manufacture. It has the benefit that the printing is not applied to the finished cylindrical tube body, but on an even surface that is rolled out on continuous rollers. The printing is applied in photographic quality and several printing processes, such as flexographic and screen printing, and embossing, can be integrated in-line. Complex printed images are therefore possible in one work step. EPL Ltd. uses the latest technology in order to guarantee a strong fusion between the shoulder and tube body. Benefits:

Benefits of the laminated tube:

- Excellent barrier properties

- Laminated tubes guarantee consistent quality

- Increase in product durability

- Print applied on an even surface - photographic quality

- Minimal material application - good price-performance ratio

- Can be adapted to a wide range of caps and closures

- Application areas in different industries are possible

- Simple handling

- Ideal dosage and emptying